Analog Panel Meters: Will the Trend Continue?

Published by Joe Legerstee on 1st Sep 2017

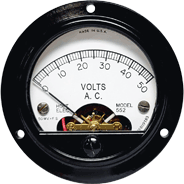

Analog Panel Meters were once used to measure AC and DC voltage and current exclusively in many products. Every older piece of test equipment available seemed to have an analog indicator of one form or another. To monitor different aspects in a circuit, some meters would indicate a rate of change, a flow, or even feel per minute a roller was traveling. As technology changed to a more multifunction sensor requirement, computer-based data acquisition and digital displays have become more popular.

DIGITAL Meters vs ANALOG Meters

As with every high-tech measuring device, more sophisticated products require more external sensors, power supplies, cabling and software, which adds cost. More problems could occur from signal amplification and or conditioning that is required to make these new measuring devices work. If the power supply is not available, an additional circuit must be installed. Signal measuring devices for temperature, current, or pressure all require signal conditioning which also adds to the cost.

|

With all this new technology, we should ask ourselves:

All of these questions should be asked before a new product design is made. Analog panel meter indication was and still is one of the least complicated and inexpensive forms of metering available. An analog meter can provide indications and trends on how a circuit is functioning. Many manufacturers use color coded dial to indicate a go/no-go situation. High-tech digitals give a number, which an operator must know if it is good or bad. If a circuit is losing power or dropping current, the analog panel meter easily indicates a drop by the pointer swinging in a downward trend. High-tech digital devices flash numbers at different speeds depending on sampling rate and speed of drop. Again, the operator must know if the numbers are good or bad. If knowing what is measured is a concern, analog meters are the easiest to scale and connect to existing voltage or currents. High tech digitals require external transducers and additional power supplies to even begin to measure this same circuit. Analog is a simple two-wire design that will give the quickest and easiest measurement of a circuit. |

Conclusion: Analog panel meters are one alternative to the high tech complex applications that many engineers are facing today. Sophisticated instrumentation panel and displays are growing at a fast pace and the demand for new types of signal measurement is reaching its peak. Analog panel meters are a simple solution to measuring and displaying required information without the cost and special circuitry required for digital or PC-based displays. Analog panel meters are here yesterday, today, and tomorrow!

More information: